Avoiding Tool Crashes

Multinational aerospace manufacturer BMT Aerospace avoids expensive mistakes with CGTech’s Vericut machine simulation software.

No shop wants to crash one of its CNC machine tools. Production suffers while the machine is down for repairs, parts are scrapped, cutting tools broken, toolholders and workholding vises damaged. The cost and downtime can be enough to disrupt the shop’s growth trajectory, sometimes permanently. This is especially true for a Swiss-made, 5-axis machining center that’s one of only a few in the United States – No. 43 in the world.

Vitaliy Tsisyk, gearbox engineering manager for BMT Aerospace International N.V., a division of the Belgium-based BMT Group, was part of the team that decided to install the high-end machine tool. He knew the stakes were too high for the traditional push-the-green-button-and-hope approach to program prove-outs. He contacted Irvine, California-based CGTech Inc. for help.

Gearing up

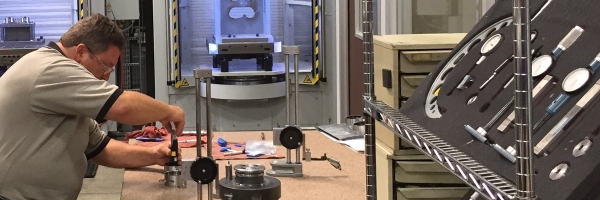

BMT Aerospace in Fraser, Michigan, is one of three plants responsible for precision machining of gears and transmission components for the aerospace industry. The others are in Iasi, Romania, and Oostkamp, Belgium. Together they produce gearboxes and housings for turbine engines, high-lift actuation gears, shafts and housings, and various splined components.

Their customers include Airbus, Boeing, Embraer, GE Aviation, Rolls Royce, and United Technologies Corp. (UTC). These customers demand zero defects and have no tolerance for supply chain disruption. Two of BMT’s three plants use Vericut toolpath simulation software from CGTech, with the third coming online shortly.

“We were the first ones to launch Vericut,” Tsisyk says. “That was five years ago. Belgium began using it a couple years after that, and we’re currently working with the Romanian plant to get it implemented there. For us, the main reason was to avoid any issues on our 5-axis machining centers. You simply cannot afford any mistakes when you’re producing expensive parts on very expensive machinery.”

A DMG MORI DIXI DHP 80 II horizontal machining center (HMC) in Frasen boasts volumetric accuracy of 25µm (0.00090″) and positioning accuracy of 0.90µm (0.00003″). The HMC primarily machines gearbox housings such as the gearbox mounted accessory drive (GMAD) used on Saab 2000 twin-engine passenger jets and Lockheed Martin C-130 military transport aircraft. Tsisyk says it also machines other parts from aluminum, magnesium, stainless steel, and titanium that demand extreme accuracy.

Edited by Michelle Jacobson

Tight quarters

Bought for the DIXI, Vericut software use has expanded to other CNC machine tools at BMT Aerospace, including a recently installed UMC-750 5-axis HMC from Haas Automation. Tsisyk says the machine cuts chamfers on the bevel gears used in power take-off (PTO) boxes and similar gearbox assemblies – extreme kinematics motion that would have been difficult to visualize without Vericut.

Vericut also prevented a near certain crash after a drive block for a right-angle head was improperly mounted on the machine tool.

“Luckily, I have a very experienced guy on the shop floor who told me he didn’t think it would clear the part,” Tsisyk says. “I brought the program into Vericut, updated the model to reflect the block’s placement and size, and sure enough, it would have crashed.”

Other applications also dealt with troublesome angle heads, where clearance between the head and the workpiece was very tight. In one example, the head was going to mill a series of internal grooves inside a cylindrical part. Tsisyk had the accessory’s advertised dimensions validated on one of the shop’s coordinate measuring machines (CMMs), then used those values to model the head exactly in Vericut.

“In this case, the gap between the two was especially critical, because if you crash a head like that deep inside a workpiece, it only takes one small mistake to break a machine, break confidence levels, and disturb the production that could delay final product delivery to our customers,” Tsisyk explains. “With Vericut, I don’t have to worry about those situations.”

Breaking the rules

Tsisyk says Vericut is not used 100% of the time at BMT Aerospace, although he’d like to see it become so.

“We don’t have a mandate that says all programs must go through toolpath simulation before being sent to the shop floor,” he explains. “Our company and many of its 150 or so employees have decades of experience with specific ways of producing specific parts. Depending on the product complexity and the confidence level of the programmers and operators involved in the setup, they may choose to rely on their own expertise to do the verification. From my side, though, I sleep very well at night knowing that all of my programs have been simulated using Vericut.”

BMT Aerospace USA Inc.

Read this User Story on Aerospace Manufacturing and Design’s website

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan