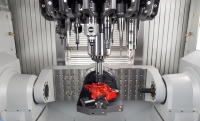

CGTech developed the CNC verification and optimization software VERICUT to reflect the actual machining environment. It analyzes and verifies tool paths and run independently from the machine. The software eliminates potential risks caused by the NC program as comparing a design model with the final workpiece, checking gauges and any possible collisions among tool, holder, machine parts and the workpiece. With CGTech’s solid partnership with global machine builders and software companies, VERICUT users can adopt the software in any machine or manufacturing process.

CGTech Korea’s country manager Lim says, “Market changes, machines evolve, and there will be always new challenges. One thing that you can always count on is VERICUT will save your time and money, and sharpen your competitive edge, no matter how large or small your operation scale is. VERICUT can enhance the effectiveness of overall manufacturing process by preventing errors, cut cost, and reduce production time. It is best proven by our widely ranged customers from global aerospace enterprises to three man job shops that VERICUT has been successfully supported for 30 years”. CGTech recently celebrated its 30th anniversary.

VERICUT offers solutions for various machining scenarios involving metal cutting, additive, or composites. The verification module, which easily and precisely finds the problem areas in the NC program, is the bases of all VERICUT modules. VERICUT optimization module optimizes the feed rate without modifying the toolpath based on cutting data such as force, removal rate, and chip thickness. CGTech Korea’s two-hour seminar will provide verification and optimization strategies especially for CNC lather and milling machining.

Lim concludes, “Expensive tools and machines will improve the machining effectiveness up to a certain level. If you want to excel, the answer can be the feed rate optimization. Korea office runs ‘FORCE optimization test’ with our customer provided NC programs and we see at least 10% of time-saving, and often times higher, in all cases”.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan