Landing gear specialists Messier-Bugatti-Dowty (Safran) in Mirabel, Quebec, verify their work upstream to ensure machining accuracy

Coming in for a landing, the majestic Airbus A330-300 wide-body aircraft will approach the runway with a maximum landing weight of 187 metric tonnes (over 412,000 lbs.) relying on the plane’s landing gear to deliver a comfortable arrival for its passengers.

Since 1991 the Mirabel, Quebec plant of Messier-Bugatti-Dowty (Safran) has specialized in manufacturing the main fitting of those landing gear. The largest component of the entire system, the main fitting is the central structural column that houses the shock-absorbing slider and is the most visible part of the landing gear aside from the tires. It’s a heavy high-value part that for 25 years this Montreal-area plant has been manufacturing, while continually refining its processes and honing its expertise to ensure these critical parts are done right the first time, every time.

Messier-Bugatti-Dowty is the global market leader in aircraft landing gear and braking systems, from design and manufacturing through to maintenance and repair, with manufacturing operations in France, the UK, Canada, Mexico and China.

Celebrating its 25th anniversary in 2016, the Messier-Bugatti-Dowty (MBD) plant in Mirabel machines, treats and paints the main fitting parts for main or nose landing gear for multiple Airbus programs including the A330 and A320 families, A380 (nose) and A350-900 (XWB), as well as Boeing’s 787 Dreamliner program.

Over the years the factory has become more streamlined and efficient despite its growing portfolio of parts. Andre Martin, manufacturing engineer director at the MBD Mirabel facility, has been at the plant since its opening—one of the first 11 hires. Martin recalls the early years when the shop, with a staff of approximately 150 people, was producing parts for seven A330 aircraft per month. Today, after multiple expansions and a current staff of around 300, the facility is manufacturing eight times that volume.

“We make a lot of chips,” says Martin, as we walk onto the factory floor. For MBD Mirabel, the machining process begins with solid metal forgings of high strength steel, 300M or 35NCD16, that can measure over 11-feet long and weigh about 12,000 lbs. With a line-up of 29 CNC machines, the Mirabel plant’s operations include deep hole boring, milling and turning performed on heavy-duty machine tools. According to Martin, the forging for the A330, which is among the heaviest in the world, weighs six tons and leaves the factory weighing around 1,500 lbs. “That’s metal removal,” he says.

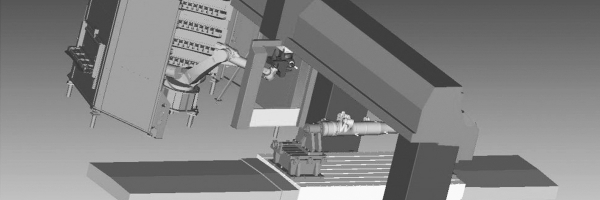

Simulation verification

Before chips begin flying on the shop floor, the manufacturing process at Mirabel begins well in advance with the programming of CAD 3D models in CATIA (Dassault Systemes) software. This is followed by post processing in Canadian-based ICAM software to generate G-code, and finally all NC programs are run through VERICUT (CGTech) simulation software.

“There is no CNC program that goes to the shop floor without having gone through VERICUT,” says Martin. MBD Mirabel has been using the machine tool simulation software since 1997 to detect any potential errors in programming that could lead to machine crashes or inefficiencies in a tool path.

“VERICUT is used so the work is done right the first time,” says Martin Reid, CNC programming coordinator. Reid, who has been with MBD Mirabel since 2006, has been a VERICUT user since 1994 and is part of the 13-person programming department at the facility.

In the front end of the plant the machine tools in operation were installed 25 years ago, and according to Martin, the ability to simulate the exact movements of those machines on the simulation software has improved their processes and saved them time. Within VERICUT the programmers use the OptiPath module, a tool that optimizes feed rates by analyzing every small segment of the tool path and assigns the best possible feed rate for each cutting condition.

This year they’ll also be testing a new Force module, an optimization program that takes into consideration the force on the cutter, spindle power and maximum chip thickness to determine maximum reliable feed rate for cutting conditions.

They also use the AUTO-DIFF feature that allows the comparison of the CAD design to the final simulation, automatically detecting and indicating differences. “We enter a model from CATIA into VERICUT to verify that we’re respecting the final envelope of the part—that we aren’t making any gouges or leaving extra material on the part,” says Reid.

“For us a gouged part is scrap,” adds Martin. “And if we have extra material we’d have to re-machine and lose time. Without VERICUT we wouldn’t be able to do the volume of work we’re doing today,” he says.

Expansion to meet demand

In April 2013 the Mirabel plant celebrated the opening of a $58 million 9,000 sq. m. (over 97,000 sq. ft.) expansion to the existing 190,000 sq. ft. facility. The new space is dedicated to Boeing 787 and Airbus A350 production, and it’s equipped with new highly-automated multi-tasking machine tools.

“Within the new shop it’s closed-door machining,” explains Martin. “Everything is automatic behind the door.”

The increased efficiency with the new machine tool technology makes it more critical that every step in the process is verified before an operator hits cycle start.

“Back when I started with three-axis machining the process was pretty simple—G-code, X-Y-Z—that was okay, but today when we look at the programs and what we are achieving on the five-axis machines, it’s a completely different ballgame,” says Martin. “It’s not possible to do all of the checking and verification manually.”

He insists their primary concern is to avoid any machine crash. It’s not only the cost related to harming the multi-million-dollar machine tools, but because of the shop’s 24/7 production schedule they can’t afford to have a machine down for even a week.

That speaks to the soaring demand in the aerospace industry. Main fittings for the A320 family account for the largest volume of parts leaving the Mirabel plant, and this past October Airbus announced plans to ramp up production of the A320/A321 program from 48 aircraft per month to 60 by mid-2019. And Boeing is continuing to ramp up production of the 787.

Continuous improvement

In the spirit of continuous improvement, the MBD Mirabel plant is also constantly seeking ways to perfect its existing processes. “We are always looking for ways to save time,” says Reid. The ability to digitally simulate operations saves process time and having to learn hard lessons on the machine tools.

The factory also holds Kaizen events to identify tasks and set goals for improvements. And although the plant’s focus is on one primary part, within each aircraft family there are often multiple models introduced. In the 787 family, for example, there is the 787-8, -9, and a -10 that’s under production. Each is a slightly different version of the aircraft, so the main fitting part is different. And every aircraft program experiences ongoing revisions that ultimately require reviewing the entire programming process.

“A revision affects not just one operation, but many different CNC operations, and we have to review every one,” says Martin.

And when new or improved cutting tools are introduced, those parameters are configured into the software and simulated for optimal efficiency.

“We’ve attained the limits on the older machine tools, and a lot of the improvements now come from new tooling. If there is a new grade being introduced to the market, then we’ll test it,” says Martin.

There is a lot of internal learning and development going on in conjunction with tool suppliers in combination with MBD Mirabel’s programmers.

“Our programming team is made up of former operators, engineers, and technicians, so it’s very diverse and knowledgeable,” says Reid.

To highlight the complexity of the work, Martin explains how it took two of the company’s programmers, working with a tooling company, one year to develop the operations for work for one part on the new machines. Next year they will be introducing the Airbus 330 NEO to their line-up, so the programming is going on now.

As aircraft OEMs continue ramping up their production it’s reassuring to observe the continuous improvement and ongoing attention to detail that exists for the parts that must handle the extreme stresses every plane experiences on touch down.

Article published in Canadian Metalworking, February 2016 (Web link)

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan