Aleris stays on the rails with VERICUT

Since Aleris Aluminium Bonn GmbH invested in VERICUT CNC simulation, verification and optimisation software the company has significantly reduced its scrap levels and made dramatic savings on the time required to introduce new components in to production.

Aleris Aluminium Bonn GmbH is one of the global leaders in the field of rolled aluminium products and sections. It supports customers in various industries include aerospace and space, road construction and civil engineering, containers and packaging, metal distribution and transport industries.

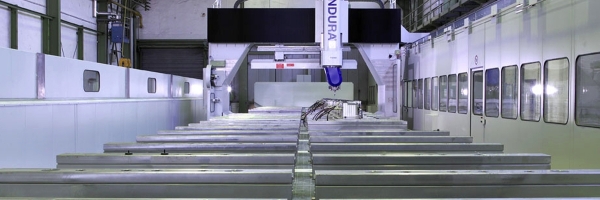

From its facilities in Bonn, Germany, Aleris Aluminium uses three continuous-feed presses to produce light weight aluminium sections for a wide range of applications in these disparate industry sectors. The company’s range of machinery is complemented by two 5-axis CNC machining centres. Main strengths in the company’s range of products include modular, partially prefabricated sections for rail wagon construction and components for the shipbuilding industry.

Size and complexity go hand in hand for Aleris’ customers. Armin Drevenstadt, Production Director of the Further Processing department, explains: “We produce continuously cast aluminium sections with complex, welded sub sections and in-fills. Predominantly for rail mounted vehicles in the railway industry, shipbuilding and vehicle construction sectors, the maximum dimensions of which can be up to 30 x 4.2 x 1.2 m.”

Invariably, the larger the component the more protracted and demanding the manufacturing processes required. The casting of the crude ingots for the continuous-feed press and the pressing of the sections are followed by straightening and thermal ageing (tempering process), before the sections are eventually welded into larger rough components and precision CNC machining is carried out. If necessary, additional welding work and further CNC machining may be carried out. The close integration of welding and CNC machining has resulted in the setting up of the Further Processing department, which has welding engineers and CNC production experts. Torsten Curdt is the Group Leader of CNC Technology and Support. Being responsible for programming and the technical aspects of CNC work, he knows all about the procedures that existed before the introduction of VERICUT.

As he recalls: “Prior to the use of VERICUT any newly written program would first have to be ‘test run’ by the programmer and the operator on the machine tool, stepping carefully through the blocks of NC code. This process meant that the cycle time was extended to around four times the predicted cutting time. The installation of VERICUT has enabled us to almost completely eradicate the ‘trial and error’ process on the machine tool and has reduced the test run time to a bare minimum.”

Since the company installed VERICUT it has been used to completely simulate CNC production independently of the machine, the NC control system and CAM software and checks the NC toolpaths for potential collisions and programming errors. Furthermore, VERICUT also optimises all the forward processing movements of the machine, so that the cutting cycle is more efficient and streamlined. The toolpaths are generated using Mastercam’s CAD/CAM software and since September 2009, VERICUT has simulated every milling path for around 120 NC programs that required cutting on the 5-axis machining centres. Also, the software ensures effective collision control between the machine’s structural elements, the cutting tool and the bespoke clamping systems fitted to the machines. This has cut the scrap levels recorded by the business from 10 per cent to just one per cent.

Since 2008, Aleris has been operating with two Mastercam and VERICUT licences and since November 2008 the company has geared the software towards a second, large travelling gantry Fooke Endura machine. First, Mastercam and the postprocessor had to be adapted to the new machine’s dynamics and this was followed by three weeks of test programming by the machine manufacturer.

Finally, in close collaboration with CGTech, Aleris selected the NC programs for the new machine and introduced a three-week trial period with optimisation by VERICUT. In March 2009, production programming and simulation began and production on the new machine eventually started in August 2009. Here too, as a result of the very high repair costs resulting from an earlier machine crash, very carefully planning was required. Week by week Aleris increased the capacities of the machine to the point where three-shift operation was possible. Since the middle of September 2009, the machine has been running at full production capacity, and as a result of the use of VERICUT, as Torsten Curdt confirms, “without any major programming faults”.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan